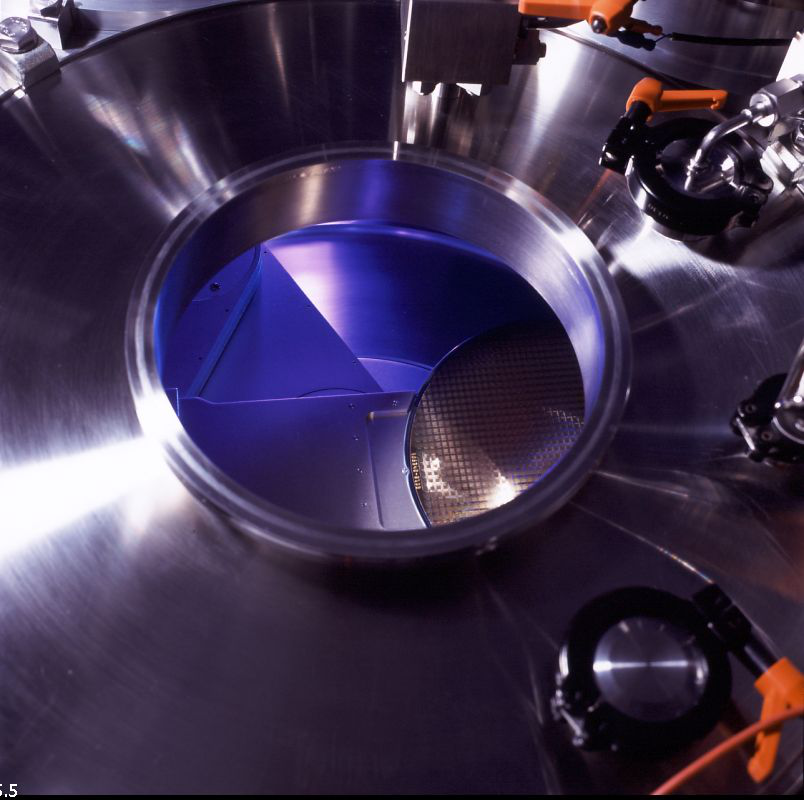

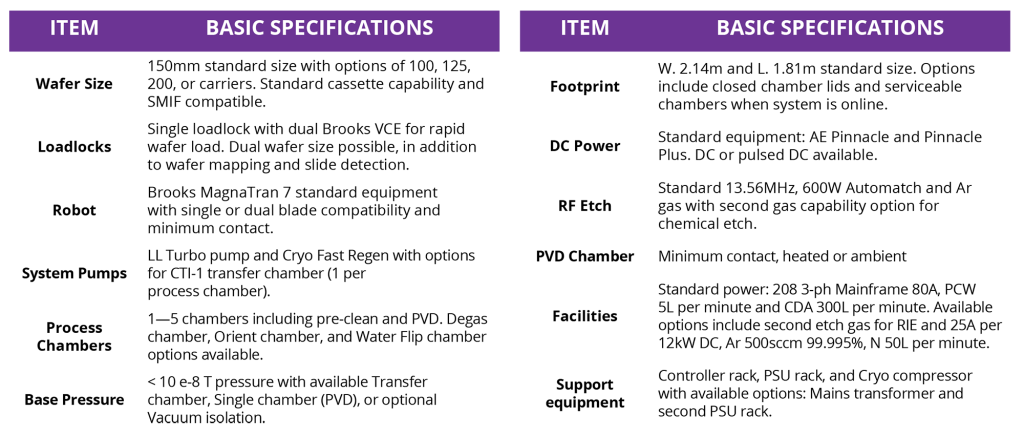

The EVOS® PVD Cluster Tool is a modular and flexible designed PVD system with a small footprint and flexible architecture that can accommodate from 100mm – 200mm wafer sizes and carriers for multiple samples/pieces. Modern design, industry standard components and ease of use make for reliable and affordable Cost of Ownership.

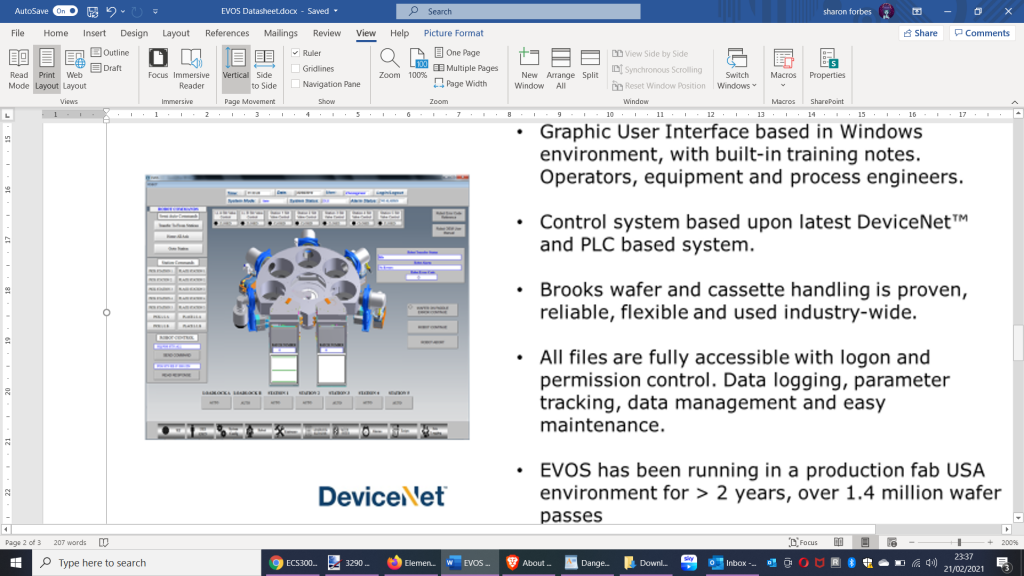

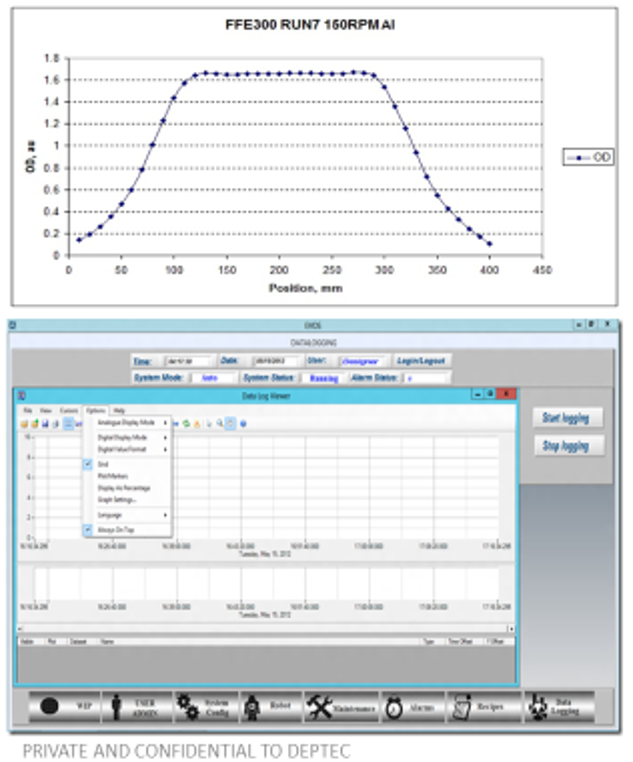

The EVOS cluster system is suitable for both R&D and full manufacturing due to the ease and repeatability of the fully automated EVOS control system, simple recipe building and repeatability mean reliable processes.

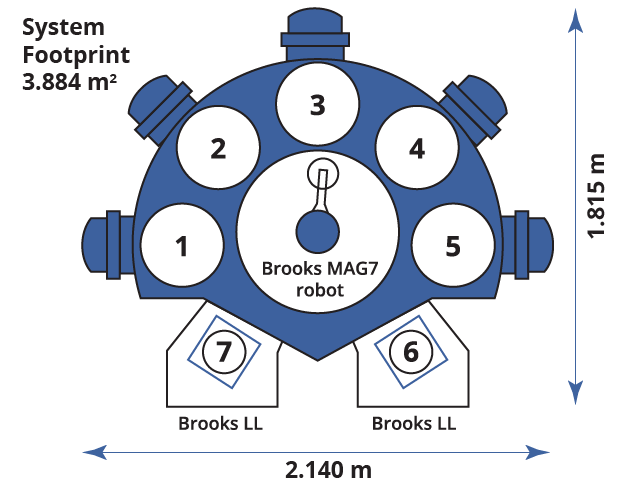

The system footprint is smaller than similar capability cluster PVD systems, meaning you can utilize cleanroom floorspace more efficiently. The load and unload cassette chambers can also be wall integrated to allow the system and ancillary equipment to be located chase side and the load/unload in the cleanroom. The innovative wafer handling design means it is perfectly set up for processing thin and non- standard wafers.

Multiple configurations and options available on request, such as heating, cooling, plasma cleaning, de-gas, RF/DC, reactive deposition, valve and pumping options to suit process and budget.